Bimetallic Plate, Bimetallic Sheet Price, Bimetallic Strip Suppliers, Bimetallic Washer Manufacturers in Mumbai, India.

Elevate your projects to new heights with the cutting-edge innovation of bimetal, a true game-changer in the world of engineering and technology. At Pearl Overseas, we’re presenting you with an opportunity to revolutionize the way you approach challenges in your industry. Our meticulously engineered bimetal plates seamlessly blend the strengths of two distinct metals, forging a material that outshines the competition. With us, you’re not just buying a product; you’re investing in a solution that delivers unparalleled performance, reliability, and longevity.

Elevate your engineering projects with top-notch bimetal products from Pearl Overseas, a trusted supplier based in Mumbai, India. Our high-quality plates, sheets, strips and washers are meticulously crafted to meet the demands of diverse industries.

Bimetal isn’t just a material; it’s a promise of excellence. Crafted with precision, our bimetal strips embody the perfect union of metals, each selected for its unique attributes. This careful pairing results in a product that not only meets but exceeds the demands of your most critical applications. From aerospace marvels to automotive essentials, our bimetal sheets creations have proven their mettle in the most demanding environments. Imagine unlocking new realms of efficiency and innovation in your projects, all powered by the exceptional capabilities of bi metal.

With Pearl Overseas, you’re not just buying a product; you’re becoming part of a movement that’s shaping the future of engineering. Embrace the power of bimetal and let your projects soar to new heights.

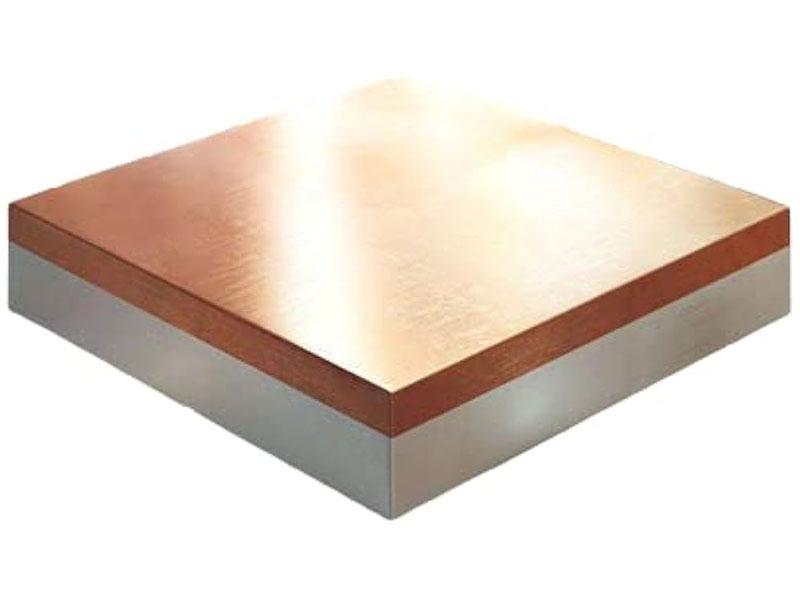

Bimetal refers to a material composed of two different metals or alloys that are bonded together. These metals typically have different coefficients of thermal expansion, meaning they expand or contract at different rates when subjected to changes in temperature. The purpose of creating a bimetallic material is to take advantage of this differential expansion or contraction. When exposed to temperature changes, the bimetal will bend or deform due to the varying expansion rates of its constituent metals. This property has various practical applications, particularly in devices like thermostats, circuit breakers, and temperature-sensitive switches.

For example, in a thermostat, a bimetallic strip is used. It consists of two metals with different expansion rates, usually steel and brass. When heated, the strip will bend in one direction, and when cooled, it will bend in the opposite direction. This bending motion is used to control a switch that regulates the temperature of a system. Bimetal is a composite material made of two different metals or alloys with distinct thermal expansion properties, commonly used in applications where temperature-related responses are needed.

These products represent the pinnacle of bimetal engineering, carefully crafted to meet the demands of diverse industries. If you’re ready to elevate your projects with the power of bimetal, explore our range and discover the possibilities.

etals Used in Bimetal: Bimetal, a marvel of material engineering, owes its exceptional properties to the deliberate combination of two distinct metals. This dynamic pairing is pivotal in crafting a material that surpasses the individual capabilities of its constituent elements. Commonly, bimetals incorporate metals with varying coefficients of thermal expansion. Copper and steel, as well as aluminum and steel, are prominent choices due to their complementary attributes.

Proportions and Alloys: The art of bimetal creation lies in achieving the optimal balance between the chosen metals. Engineers meticulously calibrate the proportions to harness the desired properties, ensuring that the resulting material exhibits enhanced characteristics compared to its individual components. Through precise alloying techniques, bimetals emerge as a testament to the potential unleashed by this harmonious union of metals.

Bimetal materials possess several distinctive properties that make them useful in various applications. Here are some key properties of bimetal:

Overall, bimetal materials are valued for their ability to respond to temperature changes in a controlled and predictable manner, making them essential components in a wide range of devices and systems, including thermostats, circuit breakers, and other temperature-sensitive applications.

Bimetal, with its extraordinary combination of properties, finds extensive application across a spectrum of industries, revolutionizing the way we approach engineering challenges. Here are some of the key domains where bimetal plays a pivotal role:

By permeating these industries, bimetal has established itself as an indispensable material, pushing the boundaries of what’s achievable in modern engineering. Its versatility and reliability continue to drive innovation and elevate the performance of a wide array of products and systems.

Selecting the ideal bimetal for your specific application is a crucial step towards ensuring optimal performance and longevity. Here are key considerations and expert recommendations to guide you in this decision-making process:

Factors to Consider:

By carefully weighing these factors and seeking guidance from experts in the field, you can confidently choose the right bimetal for your application, setting the stage for a successful and reliable end product.

Pearl Overseas stands as the unparalleled leader in the bimetal industry, boasting decades of expertise and a team of seasoned professionals with extensive technical knowledge. What sets us apart is our commitment to providing tailored solutions; we understand that every project is unique, and our bimetal products are meticulously engineered to meet your precise specifications. With a focus on employing cutting-edge manufacturing technologies, we ensure that each product, whether it’s a plate, sheet, strip, washer, or specialized alloy like copper-aluminum, meets the highest standards of quality and performance.

Our competitive pricing, combined with a dedication to timely delivery, guarantees you receive top-notch bimetal solutions without compromising your budget or project timelines. Additionally, we’re deeply committed to sustainability, prioritizing eco-friendly practices in our manufacturing processes. With a customer-centric approach, our support team is always ready to provide expert guidance and tailored solutions. The proven track record of successful projects and satisfied clients underscores our ability to consistently deliver bimetal solutions that surpass expectations. Choose Pearl Overseas for a partnership founded on quality, innovation, and unwavering dedication to your success.

Bhagirathi Bhavan, Ground Floor, Shop No. 5 1st Panjrapole, Near Gulalwadi Circle, Bhuleshwar, Mumbai – 400004, Maharashtra, India

+91-9172333437 / 9967598161

© 2023 Pearl Overseas. All rights reserved.

Designed & Marketing by Vebiotic Web Solutions

WhatsApp us